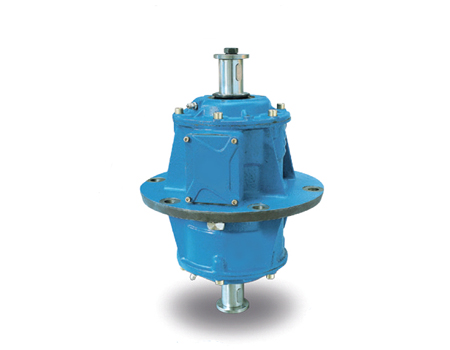

Foot Base Mounted Motor

Sonal has a wide range of FOOT BASE VIBRATORS MOTORS to meet the requirement of various industries where in material handling plays a major role. These vibrators help to empty, dose, convey, loosen, test, clean, screen, compact, distribute, feed etc., & therefore have a very wide application in Mining, Fertilizer, Chemical, Parma & Food Industry etc

Sonal-FOOT BASE VIBRATORS MOTOR vibrators Motors are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. When used as a single unit, they impact circular vibrations. If directional vibrations are needed, two vibrators running in the opposite direction should be use. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements.

Salient Features: Sturdy & robust construction.

- Totally enclosed dirt & dust proof construction.

- Amplitude of vibration can be controlled.

- Heavy-duty bearings for long & trouble free operation.

- Centrifugal force can be adjusted from zero to maximum.

- Low noise as compared to Electromagnetic Vibrators.

- Low maintenance due to absence of belts, pulleys, chains sprockets etc.

Application in various industries:

- Construction industry

- Industry of building materials

- Mining industry

- Chemical industry

- Packaging and food industry

- Mechanical engineering

Application techniques:

- Compaction

- Transport

- Evacuation / emptying

- Screening / grading

- Draining

- Dosing

- Deaerate

- Distribution

- Sizing / sorting

- Dust collection

- Loosen up of bulk materials

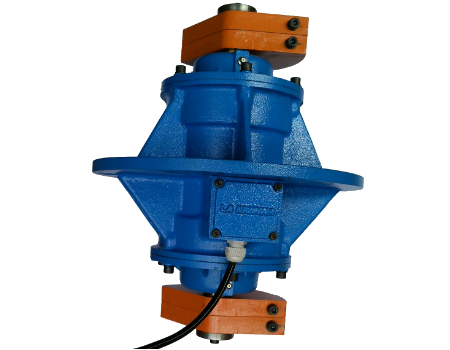

Center Flanged Motor

Sonal has a wide range of CENTER FLANGED VIBRATORS MOTORS with flange fixation, covering all the applications needs on vibrating equipments for screening, finishing, drying and other processes that use vibrating motors with this fixing system.

SONAL-CENTER FLANGED VIBRATORS MOTORS are robust, reliable, highly loadable, quite running and require no maintenance are totally enclosed, surface cooled units operating 415 / 440 volts, 3 phases, 50 & 60 cycles. A.C. Supply. Generously dimensioned cylindrical roller bearing, self-lubricating maintenance-free, long life expectancy. The vibrating frequency depends on the revolutions of the rotary unit & can be chosen from four ranges available via, frequencies are 3000, 1500, 1000, 750 vibrations per minute. The Centrifuge force can be adjusted from zero to maximum by manipulating the relative positions of the eccentric weights provided on either side of the shaft. Various models are available giving a wide choice of Centrifugal force, frequency of vibration, mounting position, Insulation etc. The customer is therefore assured of getting the most suitable vibrator to meet these requirements.

Three Phase Input Voltage:

Standard executions 50Hz 220-230/380-400V , 60Hz 220-240/440-480V (for series EVR-EVS 50Hz 380-400V; 60Hz 440-480V). Special input voltages available on request.

Speed (vibrations/minute):

Standard: 2 poles: 3000 rpm - 50Hz 3600 rpm - 60Hz

4 poles: 1500 rpm - 50Hz 1800 rpm - 60Hz

6 poles: 1000 rpm - 50Hz 1200 rpm - 60Hz

On Request:

Speeds not listed as standard two speeds motors 3000/1500rpm or

1500/1000rpm

Duty

Continuous duty at the maximum centrifugal force (S1), with the possibility

to adjust the force from 0 to 100% following the specific graded plate on

the eccentric weights (for those series/models supplied by OMB complete

with weights).

Electric Motor

Electric motor realized with low loss silicium magnetic lamination core

allowing increasing the efficiency while reducing heating up.

Insulation Class :

F standard, H on request.

Tropicalisation:

Windings impregnation realized with ASTM system, with polyester resin

class H.

Ambient Temperature:

From -20°C a +40°C (-4°F/104°F).

Overheating Protection:

Electric motor protected by Thermistor (PTC set at 130°C) as standard for

sizes 50 and 70 (available on request on smaller sizes).

Motor Shaft:

Shafts in NiCrMo steel, heat treated.

Main Body:

Mechanical structure designed to withstand the high stresses, realized in

cast iron high resistance

Painting:

Electrostatic powder painting, epoxy-polyester, polymerized in oven. Color:

Blue RAL 5010.

Bearings and Lubrication:

High load capacity bearings, in special executions to withstand the stresses

of high centrifugal forces and vibrations, over-dimensioned to grant

maximum reliability in vertical use. Special “Long Life” grease lubrication.

Mechanical seals with low friction to grant excellent protection, without

over-heating and without extra power absorption, keeping their efficiency for long time. Some models as a standard, others on request, are provided

with bearing housing with double lubrication entry, to grant that

lubrication grease inlet is always from upper side of the bearing.

Available on Request:

Eccentric weights provided

A weight covers for all

We are Manufacturer, Supplier & Exporter of

Vibrating Motor, Vibrator Motor, Unbalance Motor, Foot Base Vibrator Motor, Foot Mounting Vibrator Motor, Center Flanged Vibrator Motor, Center Flanged Vibrating Motor, Vibrating Screener Feeder Machine Motor,

Sizing | Sorting Machine Motor, Compaction Machine Motor, Distribution Machine Motor, Vibrating Equipment Motor, Vibro Finishing Machine Motor, Vibroting Tumbler Screening Machine Motor,

Sifter Machine Motor, Vibro Sifter Machine Motor, Vibro Sweing Machine Motor, Grader Vibratinory Screening Machine Motor.